Multifunctional Equipment

HBQ-922 is a machine that processes twisted pairs, for automatically cutting, stripping, seal inserting, crimping and twisting. Wires with cross sections ranging from 2 × 0.3 mm² to 2 × 2.5 mm² can be processed efficiently.

● Labor Save: can realize cutting, crimping, seal inserting and twisting at the same time;

● Moving Save: remove the material moving from crimping machine to twisting machine;

● High Efficiency: the highest processing efficiency can be up to 4.5s;

● Pitch length Accuracy: within ±10%;

● High flexibility: process of twisted pairs, single wires and dual wires.

| Type | : | HBQ-922 |

| Wire Cross Sections | : | 0.3~2.5mm² |

| Wire Length | : | 300~4000mm |

| Machining Accuracy | : | ±(0.3%L+1.5mm),L表示线长 ( Wire length) |

| Stripping Length | : | 0.1~18mm |

| Open Length ends | : | 35~90mm |

| Pitch Length | : | 5~80mm accuracy:±10% |

| Feeding Speed | : | 3m/s |

| Noise level | : | <75dB(Without crimping) |

| Temperature | : | -5~+40℃ |

| Air Supply | : | 0.5~0.7MPa |

| Power Supply | : | 3×380V/50Hz |

| power | : | 8kW(max) |

| Dimensions | : | L9000×W2200×H2000 |

| FSA-001 Seal loading machine FSA-001 | ||

| Optional Accessories | DOS Servo crimping machine | |

| Frequency conversion crimping machine | ||

| Shut height measurement module | ||

| Terminal Pull Force detection module | ||

|

|

HBQ-901 HARNESS PROCESSING CENTER

The HBQ-901 harness processing center can perform the functions of cutting, stripping, sealing, crimping and inserting terminals into connector and it can process wires up to 6, saving a lot of manpower for wire harness manufacturers, effectively reducing the number of products in progress, increasing the company’s market response sensitivity and improving product quality. This product is suitable for the production of large order quantity and less than or equal to 6 kinds of wiring harness, and the relative efficiency is higher. This type of equipment adopts modular design ideas, can provide customized services, and flexibly adjust the station layout according to the actual production conditions of customers, which has good market applicability. 查看详情

HBQ-902 HARNESS PROCESSING CENTER

The HBQ-902 harness processing center can perform the functions of cutting, stripping, sealing, crimping and inserting terminals into connector and it can process wires up to 48, saving a lot of manpower for wire harness manufacturers, effectively reducing the number of products in progress, increasing the company’s market response sensitivity and improving product quality. The device can adapt to the situation of simultaneous insertion with multiple sheaths, and has better compatibility with a variety of insertion ends and complex insertion techniques. This type of equipment adopts modular design ideas, can provide customized services, and flexibly adjust the station layout according to the actual production conditions of customers, which has good market applicability. 查看详情

HBQ-G511 Automatic Single Wire Stranding and Inserting Machine

HBQ-G511 Fully automatic single wire stranding and inserting machine is a kind of automatic wire harness processing equipment with one end crimping, tail tinning and stranding and inserting the shell, including terminal crimping, tail tinning, terminal CCD appearance detection, terminal insertion force pulling force detection, pin crimping, terminal housing, stranding shell and other functions, suitable for automotive wire harness, home appliance electronic wire. The layout of the whole machine adopts modular design, high efficiency, convenient debugging, modular change, high efficiency, Key components of the whole machine are imported or well-known domestic brands to ensure the reliability of the equipment. HBQ-G511 Fully automatic single wire stranding and inserting machine, the whole machine includes: a set of main machine, a set of pay-off machine, the main machine can process 50mm-600mm long wire, processing 0.04mm²-2mm² wire. 查看详情

HBQ-G511B Fully Automatic Single Line Single End Shell Insertion Machine

HBQ-G511B is a fully automatic double-ended crimping and single-ended shell insertion wire harness processing equipment. Its functions include terminal crimping, terminal CCD appearance inspection, terminal insertion force and pull force testing, terminal shell insertion, etc. It is suitable for automotive wire harness and home appliance electronic wires. The layout of the entire machine adopts modular design, which is efficient and easy to debug. Modular transformation is adopted, which is efficient. The key components of the entire machine are imported or from well-known domestic brands to ensure the reliability of the equipment. HBQ-G511B machine includes: one main unit and one pay-off machine. The main unit can process wires ranging from 60mm to 2000mm in length and from 0.1mm² to 2.0mm². 查看详情

HBQ-G512 Fully Automatic Double-Head Housing Insertion Machine

HBQ-G512 is a kind of fully automatic double-head terminal crimping, double-head single-wire shell insertion harness processing equipment,processing products suitable for automotive wire harness and home appliance electronic wire.The whole machine layout adopts modular design, high efficiency and convenient debugging.The equipment is equipped with terminal pressure detection, peeling CCD detection (optional), core number CCD detection (optional), terminal CCD appearance detection (optional), terminal insertion force detection, terminal pulling force detection,to prevent the outflow of inferior products.Key components are imported or well-known domestic brands to ensure the reliability of the equipment. 查看详情

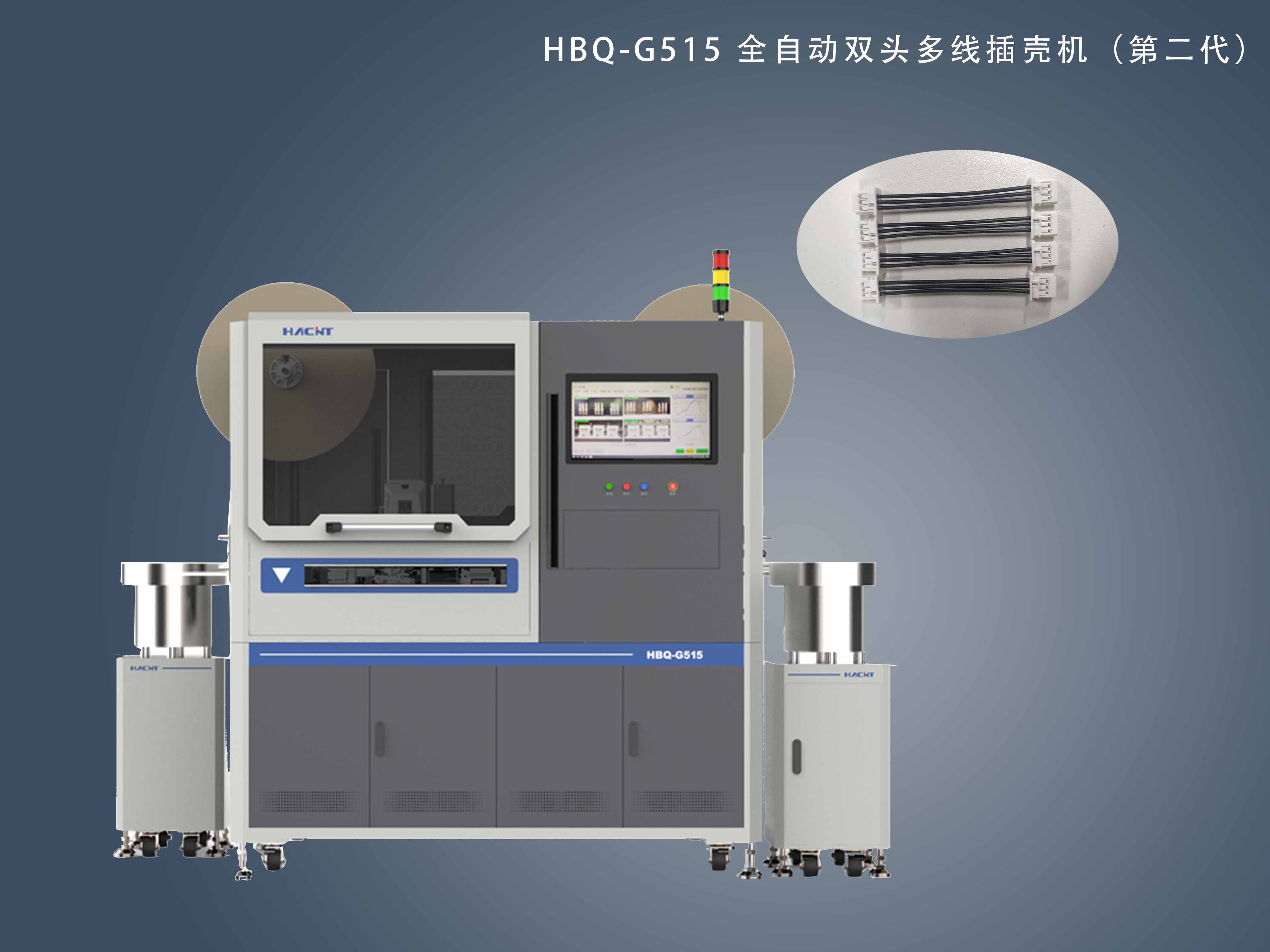

HBQ-G515 Fully Automatic Double-Head Multi-Wire Shell Inserting Machine (Second generation)

HBQ-G515 fully automatic double-head multi-wire shell inserting machine (second generation) is a fully automatic double-head multi-wire harness processing equipment of wire terminal crimping, inserting shell, tail tinning or double-head multi-wire inserting shell, suitable for automotive wire harness, home appliance electronic wire and line. The layout of the whole machine adopts modular design, high efficiency, easy debugging, support for rapid type change, 1 hour change completed. The equipment is equipped with terminal pressure detection, peeling CCD detection (optional), terminal CCD appearance detection (optional), terminal in place CCD detection (optional), NG cut off anti-stay, to prevent the outflow of inferior products. Key components are imported or well-known domestic brands to ensure the reliability of the equipment. 查看详情